Designing Production Processes for Food Manufacturing Plants: A Comprehensive Guide

Designing the production process for a food factory is a complex, multidisciplinary endeavor that integrates principles of food science, engineering, economics, and regulatory compliance. An effective design ensures product safety, quality, and consistency while optimizing efficiency and cost. This paper outlines the key steps and considerations in designing a food plant production process, serving as a foundational guide for such projects.

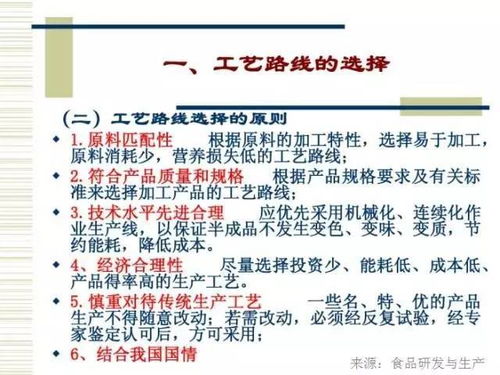

1. Product Definition and Process Selection

The design journey begins with a clear definition of the final product(s), including its physical, chemical, microbial, and sensory specifications. Based on this, the core unit operations are selected. These are the fundamental physical or chemical transformations, such as cleaning, sorting, mixing, heat processing (e.g., pasteurization, sterilization, baking), cooling, fermentation, extrusion, packaging, and labeling. The sequence of these operations forms the basic process flow.

2. Development of the Process Flow Diagram (PFD)

The selected operations are formalized into a Process Flow Diagram. The PFD is a schematic representation that shows the major equipment and the flow of materials (ingredients, intermediates, final product, and by-products) through the plant. It does not include minor details like valves or instruments but focuses on the core process steps, serving as the conceptual blueprint.

3. Mass and Energy Balance Calculations

A rigorous mass and energy balance is the quantitative backbone of the design. It involves calculating the inputs (raw materials, water, steam, energy) and outputs (product, waste, emissions) for each unit operation and the entire system. This step is crucial for:

- Sizing equipment (e.g., tank volumes, conveyor capacities, heater power).

- Determining raw material requirements.

- Estimating utility needs (water, electricity, steam, compressed air).

- Identifying waste streams for management.

4. Equipment Selection and Specification

With quantitative data from the mass balance, specific equipment is selected. Key factors include:

- Hygienic Design: Equipment must comply with standards like EHEDG or 3-A Sanitary Standards. Surfaces should be smooth, non-porous, corrosion-resistant (e.g., stainless steel 316), and easily cleanable (CIP - Clean-in-Place capabilities are often essential).

- Capacity and Scalability: Equipment must meet target production rates with some design margin for future growth.

- Process Control: The level of automation (manual, semi-automatic, fully automatic) is defined. Sensors for temperature, pressure, flow, and pH are integrated for monitoring and control.

- Reliability and Maintenance: Ease of access for maintenance and cleaning is paramount.

5. Plant Layout and Material Flow Design

The physical arrangement of equipment and spaces is designed to ensure:

- Logical Flow: A linear, smooth progression from raw material receiving to shipping, minimizing cross-traffic and backtracking. This is often conceptualized as a "straight-line flow."

- Zoning and Separation: Strict segregation of areas based on hygiene risk (e.g., raw material area, processing area, high-care/high-risk area for ready-to-eat foods, packaging area). This prevents cross-contamination. Air pressure differentials are used to control airflow from clean to less-clean areas.

- Personnel and Utility Flow: Separate pathways for personnel movement, waste removal, and utility lines (water, electricity) to avoid contaminating product streams.

- Flexibility: For multi-product facilities, layout should allow for changeovers and cleaning with minimal downtime.

6. Integration of Food Safety Systems

Process design is intrinsically linked to food safety. Key systems must be integrated from the outset:

- Hazard Analysis and Critical Control Points (HACCP): The process is analyzed to identify biological, chemical, and physical hazards. Critical Control Points (CCPs), like a kill step during thermal processing, are identified, and control measures with critical limits, monitoring, and corrective actions are established.

- Sanitation: The design must facilitate effective cleaning and sanitation. This includes sloped floors for drainage, coving at floor-wall junctions, the use of hose stations, and the design of CIP systems.

- Allergen Control: Dedicated equipment or rigorous cleaning protocols must be designed for handling allergenic ingredients.

7. Utility and Support Systems Design

The "backbone" systems that enable the process must be designed:

- Water: Potable water supply, possibly with on-site treatment (filtration, softening).

- Wastewater: Pre-treatment systems to meet municipal discharge standards.

- HVAC (Heating, Ventilation, and Air Conditioning): Critical for temperature and humidity control, especially in sensitive areas, and for maintaining positive/negative air pressure cascades.

- Energy: Steam boilers, refrigeration systems, and compressed air.

8. Automation and Control Systems

A modern food plant relies on a Supervisory Control and Data Acquisition (SCADA) system or a Distributed Control System (DCS). This allows for:

- Automated control of process parameters (e.g., retort temperature-time profiles).

- Real-time monitoring and data logging for quality and safety records.

- Alarm systems to alert operators of deviations.

- Traceability, linking production batches to specific raw material lots and process conditions.

9. Regulatory and Standards Compliance

The design must adhere to national and international regulations (e.g., FDA regulations in the USA, EU food hygiene regulations, local building codes). Adherence to voluntary standards like ISO 22000 (Food Safety Management) or BRCGS/IFS Global Standards is often a market requirement and should be designed into the facility.

Conclusion

Designing a food factory production process is a systematic exercise that balances scientific rigor with practical engineering. It moves from the conceptual (product definition) to the highly detailed (equipment specifications and control logic). A successful design is one that is inherently safe, hygienic, efficient, and adaptable, providing a robust foundation for producing high-quality food in a sustainable and profitable manner. Future trends, such as the integration of Industry 4.0 technologies for predictive analytics and greater sustainability through resource recovery, will continue to shape the design paradigms for the food factories of tomorrow.

如若转载,请注明出处:http://www.lw-sky.com/product/279.html

更新时间:2025-12-22 03:04:34